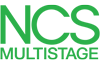

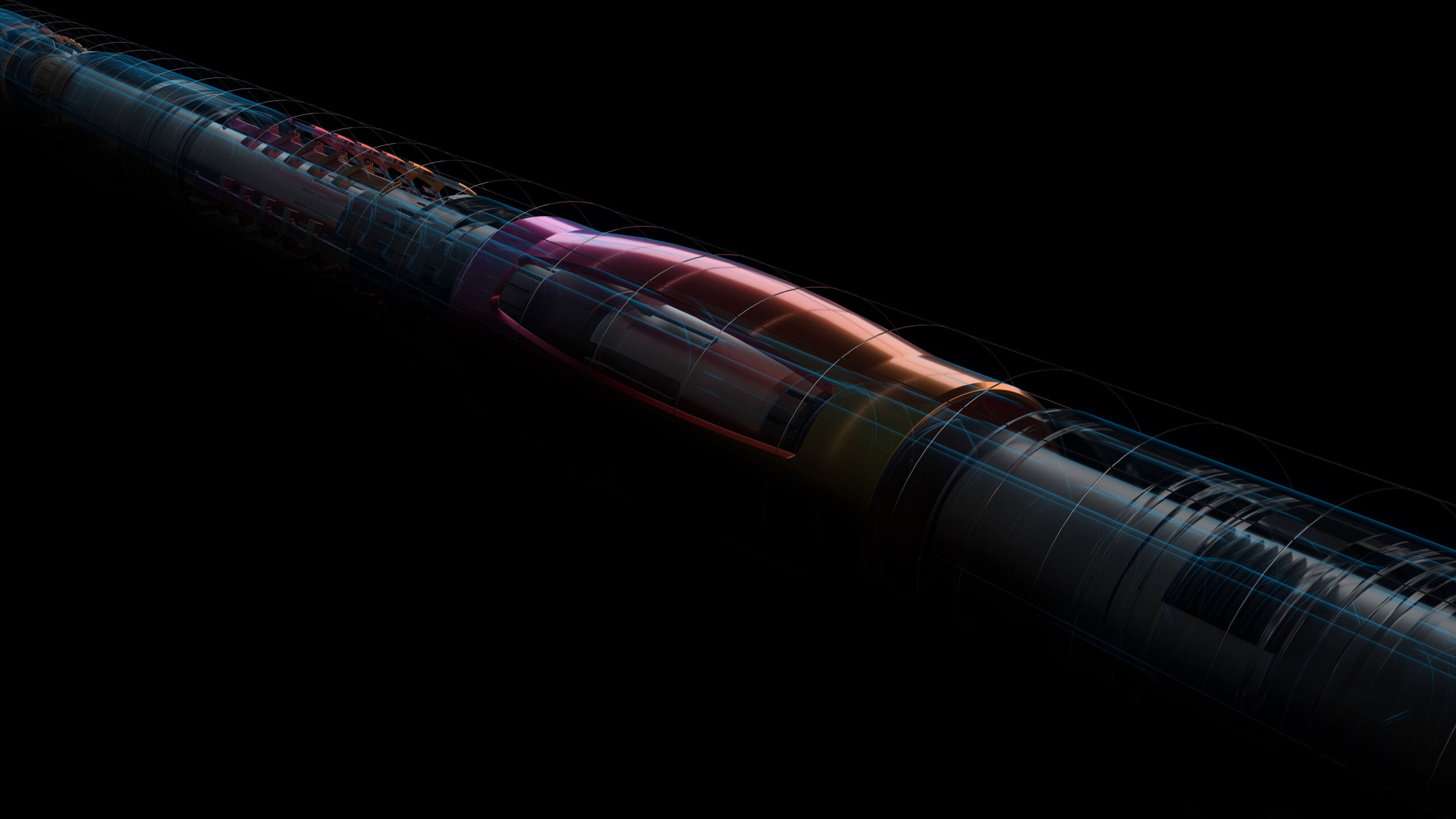

Innovus™ Geothermal

Amplify recovery in extreme conditions. Discover a smart stimulation solution that delivers enhanced flow control—even in the hottest geothermal environments.

Innovus™ Geothermal

Amplify recovery in extreme conditions. Discover a smart stimulation solution that delivers enhanced flow control—even in the hottest geothermal environments.

Innovus™ Geothermal

We are committed to providing our clients with innovative solutions that foster economic growth, ecological responsibility, and enhanced safety.

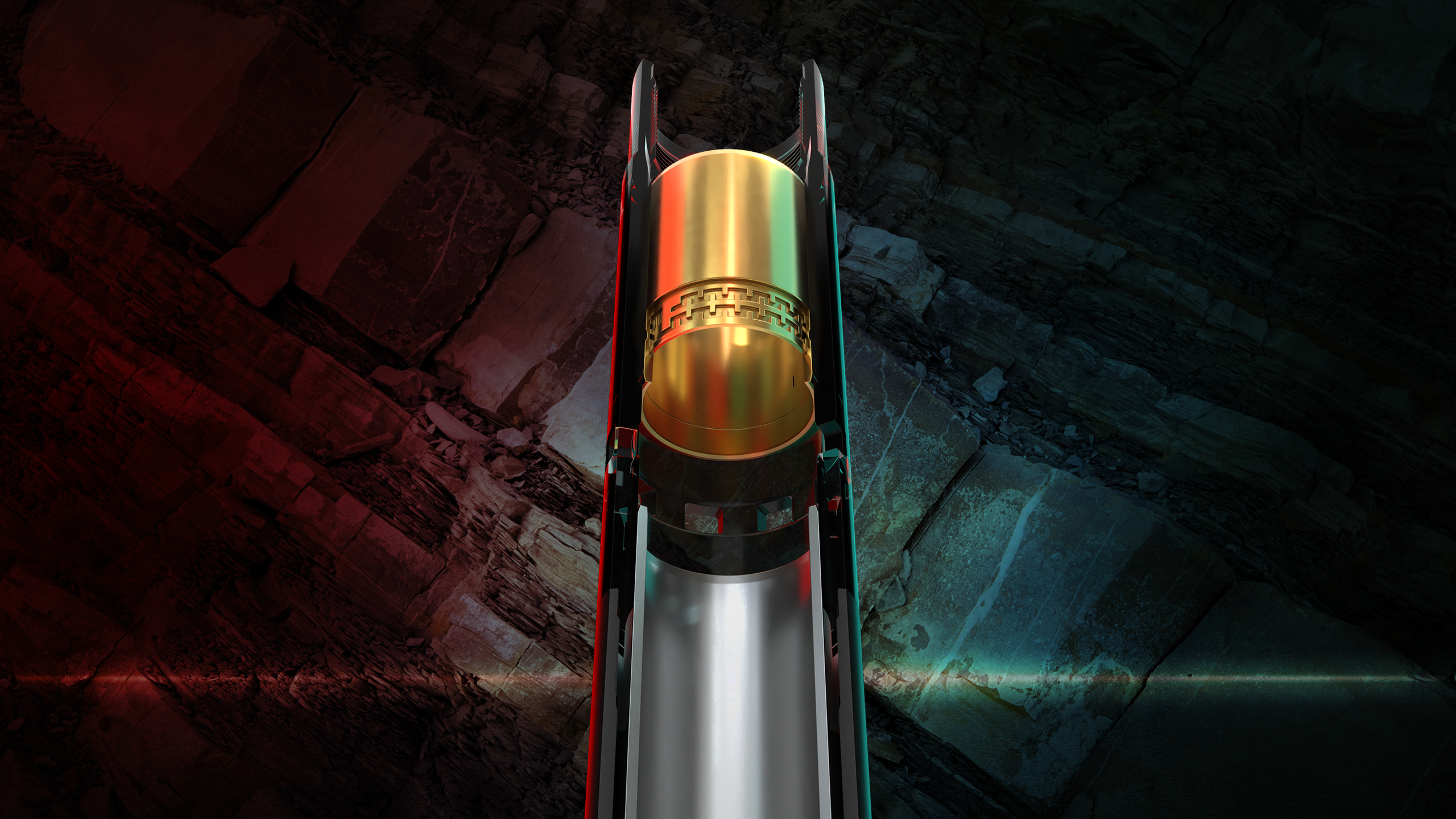

One Source. Many Solutions.

NCS Multistage manufactures solutions for all stages of energy production.

We provide the most innovative, tested, and reliable solutions for the most demanding applications.

Setting Standards

Our experience and love for innovation converge in a consistent effort to set new industry standards.

Wells Traced

Screenouts Managed

Bn

Lbs of Proppant Placed

Our Customers